PERFUME MAKING NOTES

TOPICS

1. What is perfume?

2. What is perfume compound made from?

3. Perfume making basics.

1. WHAT IS PERFUME?

From Latin “Per” Through “Fumum/Fumus” Smoke, like prayers or messages sent through smoke from fragrant woods and spices as incenses in religious ceremonies.

Perfume is a complex mixture of aroma chemicals (even if they are from essential oils). When you spray a perfume, the liquid volatilized into vapour as it diffuses into the air. The gaseous state of perfume compound is what gives its aroma. Perfume can be converted into a solid by freezing it.

Perfume is a mix of compound, solvent and additives. Perfume compound or concentrate is comprise of Natural Materials, Synthetic Materials, Animal Materials and Specialty Bases.

Perfume is communication – image/feelings/personalities you want to portray or aspire and not who you are.

Smell evoke emotions and memories.

Smelling exercise the brain.

PERFUME AND THE LIMBIC SYSTEM

Emotion and memory is very closely linked to the brain’s anatomy. Smells are transported to the olfactory bulb, a structure in front of the brain that sends information to other areas of body’s central command for further processing. Odors take a direct route to the limbic system, including the amygdala and the hippocampus, the regions related to emotion and memory.

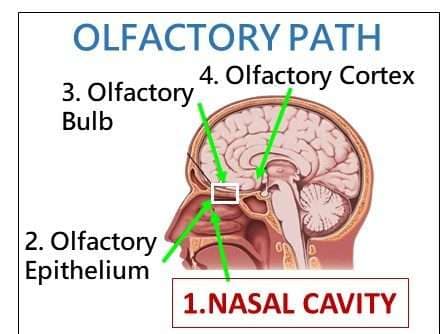

OLFACTORY PATH

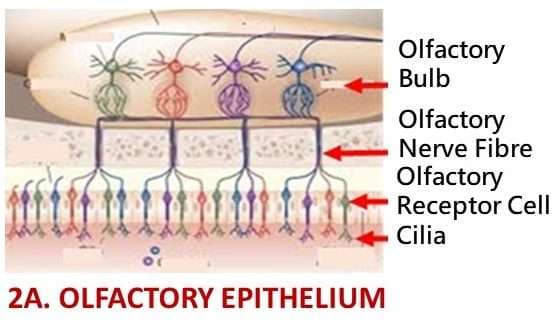

Olfactory epithelium, the specialized region of tissue lining nasal cavities, contains olfactive receptor cells, which have specialised cilia extensions.

The cilia trap odor molecules as they pass across the epithelial surface and send odor information to olfactory bulb.

Olfactory bulb sends information to other areas of the body’s central command for further processing including the limbic system.

The limbic system is that part of the brain involved in learning, memory, emotion and motivation.

Olfactory cortex, a component of the limbic system, has connection with the limbic system structures. Eg amygdala (involved in forming emotional responses, particularly fear responses, and memories); the hippocampus (indexes and stores memories) and hypothalamus (regulates emotional responses).

2. WHAT IS PERFUME COMPOUND MADE FROM?

2.1. Essential oils – water/steam/water and steam distillation

2.2. Essential oils – citrus oil expression (cold press)

2.3. Essential oils – dry/destructive distillation

2.4. Essential oils – infused plant

2.5. Essential oil – plant tincture

2.6. Natural isolates – fractional distillation

2.7. Natural isolates – cooling method

2.8. Natural isolates – selective solvent extraction

2.9. Natural extracts – solvent extraction

2.10. Natural extracts – supercritical fluid CO2 extraction

2.11. Natural extracts – cold enfleurage/absorption

2.12. Natural extracts – hot enfleurage/maceration

2.13. Natural extracts – resinoids, resins, balsams, oleoresins and gums

2.14. Semi-synthetic material of natural origin – Isolate of essential oils

2.15. Semi-synthetic material – chemically modified isolate of essential oils

2.16. Semi-synthetic material – nature identical chemicals

2.17. Completely synthetic aroma materials

2.18. Animal tinctures

2.19. Speciality bases

2.1. ESSENTIAL OILS – WATER/STEAM/WATER AND STEAM DISTILLATION 15%

Essential oils are complex mixtures of volatile natural occurring chemical components which give its unique odour. Separately, plant parts are permeated with steam to capture the compounds that produce fragrance. Plant tissues break down to release essential oil and water vapour. Oils float on cooled water allowing it to be separated, collected and cooled. It can take several pounds of a plant to produce a single bottle of essential oil. The oil is usually light colour. Colour molecules are generally large and not volatile. The decanted water is scented and can be used directly (rose water, orange flower water etc).

2.2. ESSENTIAL OILS – CITRUS OIL EXPRESSION (COLD PRESS) 15%

Expression only applies to citrus oils like sweet and bitter orange, lemon, lime, mandarin, tangerine, bergamot, grapefruit, kinnows etc. It is a process where essential oils held in tiny translucent sacs in citrus outer colored peels/rind is released by squeezing in presses (conventional method) or rasping the skin.

Much citrus essential oils nowadays are by-products of the concentrated citrus juice industry. Oils obtained by expression are very thin and are lighter colour version of its fruit and will fade over time except mandarin and tangerine which will get darker in color.

In the rasping method, essential oils come out from citrus skin upon rasping of rotating cylinders and is carried out by sprayed water. The emulsion (mixture of water and essential oil) flows into 2 stage finisher to remove the solids debris. The emulsion is pumped into a buffer tank and then to two centrifugal separators. The first one removes the residual debris, the second one separates the water from the pure essential oil. The water of the first centrifugal separator is pumped in a decantation tank, then through a centrifugal pump goes into a double filter and at the end goes back to the oil extractor to start the cycle again.

2.4. ESSENTIAL OIL – INFUSED OIL 10%

Fill a bottle with plant parts.

Add in oil at above plant level.

Refrigerate for a few months.

Plant goodness will transfer to the oil.

Filter the infused oil before using.

2.5. ESSENTIAL OIL – PLANT TINCTURE 10%

Grind hard and dry plants and fill up a bottle.

Submerge plants in alcohol.

Leave for a few months.

Solution level will lower due to alcohol evaporation.

When the solution reach a desired scent, filter out the residue.

2.6. NATURAL ISOLATES 10%

By temperature & pressure, chemical components of essential oils will evaporate one by one and separately. The more volatile chemical components will evaporate first.

2.7. NATURAL ISOLATES – COOLING METHOD 10%

MENTHOL CRYSTAL is a natural chemical found in mint plants obtained by isolation and crystallization. Cooling/temperature method is used to separate menthol from the liquid part. No chemical reaction is involved

ABSOLUTES

Some plant materials do not give up its fragrant oils to distillation. Jasmine or carnation flowers when steamed in a still, the waxed petals will block the tray holes. For higher volatile yields on hard waxy plants, volatile organic hydrocarbon solvents e.g. petroleum ether, hexane, cyclohexane are used to extract them. The preparation of plant materials for distillation depend on the plants specific characteristics.

Woody stems and roots may be dried out for a day or two to reduce moisture. Petals may be picked in the early nights and dropped straight into the extracting solvent. Other materials may require slicing or chopping.

The prepared materials are layered on perforated grid trays to stop it caking together and the solvent flows filling the still and flushes through the materials. As the solvent soaks into the plant materials, the cells rupture and the volatile oils dissolve into the solvent. At the same time, some non-volatile oil also dissolves together with waxes and color molecules.

The mixture of solvent and extracts passes from the still into an extractor where gentle warming allows the volatile solvent to evaporate leaving the mixture of volatile oil, non-volatile oil, waxes and color.

The waxes in the mixture solidify into a solid dark-colored mass called a concrete, a great way to store the extract for future use. The waxes which are mixed with terpenes etc are insoluble in alcohol, are usually removed by washing the concrete in a hundred percent pure ethanol under gentle warming. The softened waxes release the volatile and non-volatile oil and color into the alcohol and the waxes fall out of solution. The alcoholic mixture is taken off and then placed into an extractor where gentle heat is used to remove the alcohol by evaporation. The process may be repeated under vacuum to release the final traces of ethanol.

The final product is often a viscous liquid, semi solid liquid, wax or even paste due to the non-volatile oil components. Beeswax and acacia absolute can be waxy while clary sage is semi solid. Absolutes are highly concentrated natural fragrance from this starting material not strictly essential oils as they are obtained through extraction with volatile hydrocarbon solvents. They are usually darker colored than essential oils as non volatile color is also extracted. They cannot be used in aromatherapy because of the presence of trace of alcohol and other components.

Absolute is regarded as the strongest aromatic product, true-to-live aroma and the most costly. Concrete and absolute can also be produced by supercritical fluid extraction (SFE) or carbon dioxide extraction (CO2). Example of plants that are extracted into absolutes are ambrette seed, angelica root, carnation, cypress, frangipani, jasmine, lavender, lily, lotus, mimosa, orange flower, orris root, osmanthus, rose, tuberose and violet leaf.

2.10. NATURAL EXTRACTS – SUPERCRITICAL FLUID CO2 EXTRACTION 1%

Carbon dioxide gas or solid dry ice, when subject to very high temperature and pressure, will turn into liquid. Liquid CO2 is used as liquid solvent to extract volatile oil similar to extract absolute process. No solvent residue remains since at normal temperature, CO2 revert to a gas and evaporate. Being odorless normal component of the atmosphere, it is non-polluting and non-flammable, very little color matter and the odor are more lifelike than essential oils or absolutes. Known as Green Technology. Expensive equipment needed to control CO2 as supercritical liquid.

2.11. NATURAL EXTRACTS – COLD ENFLEURAGE/ ABSORPTION 1%

- this method applies for delicate and moist plants.

It protect the delicate aroma that may decrease by heat

e.g. jasmine, tuberose, gardenia or violet - Principal town Grasse, Cannes and Nice

- Strew plants on glass trays (called chassis) with unscented film of solid fat (lard, shea butter, cocoa butter and vegetable shortening).

- When fat has exhaustly absorb most of floral aromatic

scented volatile oil emanated from petals, renew

(usually 2-3 days) with fresh flowers. - Fats saturated with flower oils, can be sold as enfleurage pomade.

- Essential oil is separated with baths of alcohol.

- Labour intensive, very expensive, but yields outstanding scents

2.12. NATURAL EXTRACTS – HOT ENFLEURAGE/MACERATION 1%

– For less delicate flowers e.g. rose, orange, violet and acacia

– Melt fat in pot

– Add plants below the fat level and stir

– When plants has wilted, the oil has change

color and saturated with smell, scoop the

materials and strain with cheesecloth

– Allow the liquid to cool.

– Macerate oil with ethyl alcohol for few weeks.

3. Perfume Making Basics

3.1. Perfume families.

3.2. Perfume pyramid.